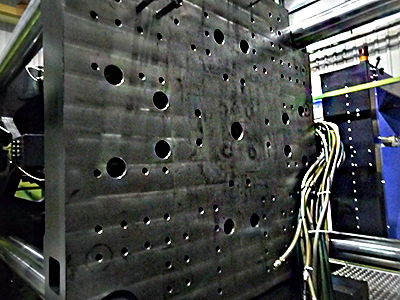

Repairs threaded holes in the moveable and stationary platens of plastic injection moulding machines

We carry out repairs, restoration, and produce of new threaded holes in the moveable and stationary platens of plastic injection moulding machines (two-platen hydraulic locking assembly).

The whole complex of works is carried out using portable equipment directly on the moulding machine.

The customer determines the technological period there being repaired during which our specialists perform these works.

Company offices are located in St. Petersburg and Tallinn.

Payment invoice are issues according to your location.

Payment invoice are issues according to your location.

Experienced repair staff speaks tolerable English.

To perform the work we have all the necessary equipment, tools and qualifications.

Send your application for work to e-mail 6434057@gmail.сom.

Phone Tallinn +372 55 92 3030

Phone St-Petersburg +7 965 747 47 27

The term of consideration of the application, two working days.

For the preparation of equipment and tools, information on the size of the holes, the thread pitch, the thread length, the number of repaired, restored or new threaded holes and the model of the repaired plastic molding machine are required.

Also our specialist can be sent to your production to determine the required parameters and familiarity with the equipment being repaired.

Technologies for repairing, restoring, or performing new threaded holes are well

established. We serve plastic injection machines. Our customers:

"KP Plastics Processing Association”; "LTO-PLAST"; MIR Upakovki; Plast Group

The total number of injection molding machines on which technologies of repair, restoration or new tapped holes were worked out - 17 machines.

The total number of threaded holes made on injection molding machines, more than 500.